While durable, concrete floors often require additional coatings to enhance their appearance, longevity, and performance. Two popular choices for coating concrete floors are epoxy and polyaspartic coatings. While each has its unique advantages, the combined use of epoxy and polyaspartic coatings can deliver superior results, leveraging the strengths of each material.

Why Use Concrete Coatings?

Coating concrete floors is essential for several reasons. Primarily, coatings protect the floor from chemical spills, physical wear, and environmental factors, significantly enhancing its durability. Chemical spills can penetrate the porous surface of uncoated concrete, causing irreversible damage and stains that are difficult to remove. Coatings provide a barrier that prevents these substances from reaching the concrete, ensuring the floor remains intact and aesthetically pleasing.

Additionally, coatings can improve the floor’s appearance, brightness of surroundings, and ease of cleaning. Concrete floors, while robust, can look dull and unattractive. Coatings come in various finishes and colors, allowing for customization that enhances the visual appeal of the space, whether it’s residential, commercial, or industrial. A smooth, coated floor is also easier to maintain, reducing cleaning time and effort.

Coatings also act as an air barrier, protecting against cold air infiltration from the concrete. This is particularly important in colder climates where uncoated concrete floors can contribute to a chillier indoor environment. By providing an insulating layer, coatings help maintain a more comfortable indoor temperature, potentially reducing heating costs.

The Benefits of Epoxy and Polyaspartic

Epoxy Coatings

Epoxy is a two-component liquid, consisting of a resin and a hardener, that cures to form a hard, durable surface that strengthens the floor. Epoxy is an economical choice for priming concrete floors and is relatively easy to apply. Epoxy’s ability to be applied in thicker layers compared to other coatings adds to its versatility, allowing for varying levels of protection and durability depending on the specific needs of the space.

Epoxy’s excellent adhesion properties make it ideal for bonding with concrete surfaces, creating a strong base for additional layers of flake and topcoats. Epoxy penetrates the pores of the concrete, providing a solid foundation that enhances the overall performance of the coating system.

Epoxy Key Benefits Include:

- Adhesion: Excellent bonding to concrete surfaces, providing long-lasting protection.

- Aesthetics: Available in various colors and finishes, including glossy and matte.

- Cost-Effectiveness: Less expensive than polyaspartic coatings.

- Low Maintenance: Smooth, non-porous surface that is easy to clean.

Polyaspartic Coatings

Polyaspartic is also a two-component technology consisting of an aspartic and a hardener. Polyaspartic coatings offer superior durability as well as chemical, scratch, and stain resistance. They are highly resistant to UV light, preventing yellowing and degradation, which is a common issue with other types of coatings. This UV resistance makes polyaspartic an excellent topcoat choice for areas exposed to sunlight, such as garages or outdoor spaces.

Polyaspartic coatings provide a high-gloss finish that enhances the visual appeal of the floor. The durability and chemical resistance of polyaspartic coatings are unmatched, making them ideal for environments that experience heavy use or exposure to harsh chemicals. These coatings are designed to withstand the rigors of industrial and commercial settings, providing long-lasting protection and reducing the need for frequent maintenance.

Polyaspartic Key Benefits Include:

- Rapid Curing: Dries quickly, often within hours, reducing downtime.

- Flexibility: More flexible than epoxy, making it resistant to cracking and peeling.

- UV Stability: Resistant to yellowing and degradation from UV exposure, suitable for outdoor applications.

- Temperature Tolerance: Can be applied in a wide range of temperatures and humidity conditions.

Advantages of Using an Epoxy + Polyaspartic Floor Coating System

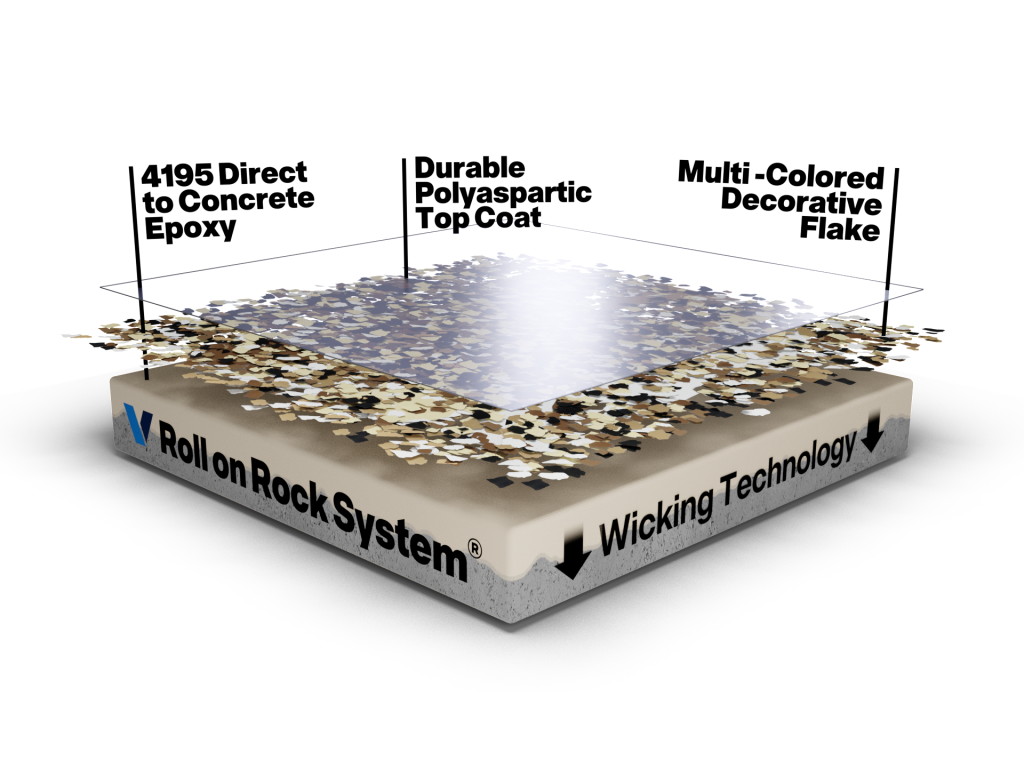

Using an epoxy and polyaspartic system – epoxy primer + flake or metallic + polyaspartic topcoat – offers several advantages. This layering approach provides optimal adhesion, durability, and aesthetic appeal. The epoxy primer ensures a strong bond by adhering to the concrete to provide a base that ensures the coating system remains strong, while the flake or metallic layers add texture and visual interest. The polyaspartic topcoat provides additional strength and protection, creating a robust and durable surface that can withstand heavy use and exposure to chemicals. This combination results in a coating system that is both visually appealing and highly functional. Further benefits include:

Enhanced Durability and Longevity

Combining epoxy and polyaspartic coatings can significantly enhance the durability and longevity of concrete floors. Epoxy’s strong adhesion provides a solid foundation, while polyaspartic’s impact resistance and UV stability protect against environmental factors and wear.

Optimized Aesthetic Appeal

Using epoxy as a base layer allows for the creation of intricate designs and patterns, thanks to its longer working time. Applying a polyaspartic topcoat can then lock in these designs, providing a high-gloss, UV-stable finish that maintains its appearance over time.

Superior Chemical and Stain Resistance

The combination of epoxy and polyaspartic ensures that a concrete floor is protected against a wider range of chemicals and stains, making it ideal for industrial and commercial environments.

Faster Installation with Reduced Downtime

While epoxy coatings require longer curing times, applying a polyaspartic topcoat can speed up the overall process. Polyaspartics rapid curing properties allow for quicker return to service, minimizing disruption to homeowners and businesses.

Improved Versatility

The combination of both coatings makes the floor more versatile, suitable for various environments from warehouses and garages to retail spaces and outdoor areas. The hybrid system leverages the strengths of both technologies, making it adaptable to different requirements and conditions.

The Versatile Difference

With over 100 million square feet of floor coating products sold, we are committed to being America’s most trusted high-performance floor coating manufacturer. Our Roll On Rock® Flake Flooring System exemplifies this commitment, combining proprietary epoxy and polyaspartic technologies to deliver unparalleled strength, durability, and aesthetic appeal. Supported by our in-house R&D and rigorous quality assurance, our flooring solutions offer exceptional performance and reliability, enhancing any residential, commercial, or industrial space.

Roll On Rock® Flake Flooring System

For over 20 years, our Roll On Rock® Flake Flooring System has been a cutting-edge epoxy and polyaspartic floor coating solution that sets a new standard for durability and aesthetics. This revolutionary system features a proprietary epoxy that wicks deep into concrete, forming a bond up to three times stronger than conventional coatings. Ideal for creating beautiful flake-enhanced floors, Roll On Rock® is further enhanced by a polyaspartic topcoat that dries fast and delivers a high-gloss, scratch-resistant finish. Homeowners can walk on their floor in 8 to 12 hours and drive on it in 72 hours.

With a long-lasting bond for durability, Roll On Rock® delivers an easy-to-apply flooring system that will withstand up to nine pounds of moisture vapor emissions (MVE) pressure, while others fail at three pounds. It provides an impact and abrasion-resistant flooring surface with as little as 2.78 mg loss compared to 28+ mg loss of other products, making it an ideal decorative floor coating system.

Roll On Rock® Attributes:

• Advanced “Wicking” Technology

• Seamless Finish

• Impact & Abrasion Resistant

• Can Apply In One Day

• Hot Tire Resistant

• Chemical Resistant

• Ultra-Low VOC

• Non-Flammable Options

• Low-Odor Options

• Durable & Easy-to-Clean

• Indoor or Outdoor Use

• High MVE Resistance

• Non-Yellowing

• Enhances Any Décor

Importance of In-House Research and Development

At Versatile, having in-house R&D capabilities is crucial for developing and maintaining high-quality products. It also enables us to stay ahead of industry trends and innovations. By continually testing and refining our products, we can ensure that we offer the best possible solutions to our customers. This proactive approach allows us to address potential issues before they arise and provide products that meet the evolving needs of the market.

Additionally, our R&D team provides technical support to marketing, sales, and customer service, ensuring that all departments are well-informed and equipped to assist customers.

“We are achieving significant advancements in flooring technology. Our epoxy and polyaspartic coating systems offer a solution that is both exceptionally durable and visually striking. Our proprietary formulas are thoroughly developed and tested, featuring superior adhesion and wear resistance that ensures our flooring systems can withstand the toughest environments. Our commitment is to consistently provide top-performing products that are versatile enough to suit any design requirement.” Versatile High-Performance Coatings® Chemist/R&D Specialist

Product Testing for Quality Assurance

We conduct extensive testing to guarantee the quality of our products. Raw materials are tested against industry standards, and we ensure proper labeling and quality control during manufacturing. Each finished product is tested at least three times before final packaging to ensure it meets our strict performance requirements.

Our products also undergo field testing in different climates and temperatures to verify their performance. This is particularly important for understanding how our products perform in real-world conditions. We also provide Technical Data Sheets, Installation Guides, and installation videos to support our customers in using our products effectively. This comprehensive approach to quality assurance ensures that our customers receive reliable, high-performance coatings that meet their specific needs.

Unmatched Flooring Solution: Combining Epoxy and Polyaspartic for Superior Results

The combined use of epoxy and polyaspartic coatings on concrete floors offers a comprehensive solution that maximizes the benefits of each material. This hybrid approach results in floors that are not only aesthetically pleasing but also exceptionally durable, chemically resistant, and versatile. By leveraging the strengths of both epoxy and polyaspartic, businesses and homeowners can achieve a high-performance flooring system that stands the test of time. Properly coated concrete floors are not only more durable and easier to maintain but also offer enhanced visual appeal, making them a valuable investment for any space. Whether for residential, commercial, or industrial use, the combination of epoxy and polyaspartic coatings delivers exceptional performance and long-lasting results.